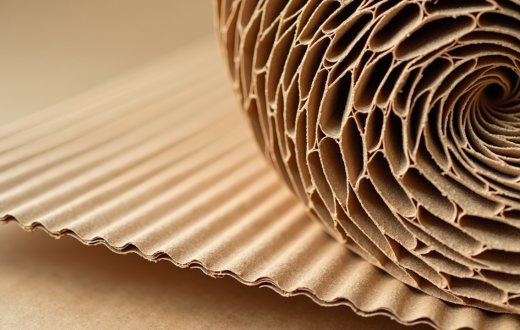

Corrugated flute packaging has become an integral part of modern logistics and product protection. This versatile material, known for its distinctive wavy middle layer sandwiched between two flat linerboards, offers a unique combination of strength, flexibility, and sustainability.

In this blog post, we’ll explore the world of corrugated flute packaging, its various types, benefits, and why it’s becoming increasingly popular in today’s eco-conscious market.

Understanding Corrugated Flute Packaging

At its core, corrugated packaging consists of three layers: an outer liner, an inner liner, and a fluted (or corrugated) medium in between. The fluted layer, which gives this packaging its name, is a series of parallel ridges and valleys that provide strength and cushioning. This structure allows corrugated packaging to be both lightweight and sturdy, making it ideal for shipping and storing a wide range of products.

Types of Corrugated Flutes

Corrugated packaging comes in various flute sizes, each designed for specific purposes:

- A-flute: The original and largest flute size, offering excellent cushioning and stacking strength.

- B-flute: Smaller than A-flute, it provides better printing surfaces and is often used for die-cut boxes.

- C-flute: A middle ground between A and B, offering good crush resistance and printability.

- E-flute: A smaller, thinner profile ideal for smaller packages and retail displays.

- F-flute: The smallest standard flute, perfect for small consumer goods packaging.

- Double Wall: Combines two layers of fluting for extra strength and protection.

Each flute type has its own set of advantages, allowing manufacturers to choose the best option for their specific needs.

Benefits of Corrugated Flute Packaging

- Excellent Protection: The fluted design absorbs shock and provides cushioning, protecting products during shipping and handling.

- Customizable Strength: By varying the flute size and combining different flutes, packaging can be tailored to meet specific strength requirements.

- Cost-Effective: Corrugated packaging is relatively inexpensive to produce, making it a cost-effective solution for businesses of all sizes.

- Lightweight: Despite its strength, corrugated packaging is lightweight, helping to reduce shipping costs.

- Versatility: It can be easily cut, folded, and shaped to accommodate products of various sizes and shapes.

- Printability: The smooth outer surface of corrugated boxes provides an excellent canvas for branding and product information.

- Sustainability: Made primarily from recycled paper and being fully recyclable itself, corrugated packaging is an environmentally friendly choice.

Environmental Impact and Sustainability

In an era of increasing environmental awareness, corrugated flute packaging stands out as a sustainable option. Here’s why:

- Recycled Content: Most corrugated packaging contains a high percentage of recycled material, often up to 70-100%.

- Recyclability: Corrugated boxes are easily recyclable, with over 90% of corrugated packaging in the US being recycled.

- Biodegradability: When not recycled, corrugated packaging naturally decomposes, minimizing long-term environmental impact.

- Reduced Carbon Footprint: The lightweight nature of corrugated packaging helps reduce transportation-related emissions.

- Reusability: Many corrugated boxes can be reused multiple times before recycling.

Innovations in Corrugated Flute Packaging

The packaging industry continues to innovate, improving corrugated flute packaging in several ways:

- Water-Resistant Treatments: New coatings and treatments can make corrugated packaging more resistant to moisture, expanding its use in various industries.

- Intelligent Packaging: Integration of QR codes, RFID tags, and other smart technologies into corrugated packaging enhances traceability and customer engagement.

- Improved Printing Techniques: Advancements in digital printing allow for high-quality, full-color designs directly on corrugated surfaces.

- Sustainable Adhesives: Development of plant-based and other eco-friendly adhesives further enhances the sustainability of corrugated packaging.

- Micro-Flute Technology: Even smaller flute profiles are being developed for specialized applications.

Choosing the Right Corrugated Flute Packaging

When selecting corrugated flute packaging, consider the following factors:

- Product Weight and Fragility: Heavier or more delicate items may require stronger flutes or double-wall construction.

- Shipping Method: Long-distance or rough shipping conditions might necessitate more robust packaging.

- Storage Conditions: Consider humidity and stacking requirements when choosing flute types.

- Printing Needs: If high-quality graphics are essential, select flutes that provide better printing surfaces.

- Size and Shape: Ensure the chosen flute type can accommodate your product’s dimensions and any unique shapes.

- Environmental Goals: If sustainability is a priority, look for options with high recycled content and easy recyclability.

Conclusion

Corrugated flute packaging has come a long way since its invention in the late 19th century. Today, it stands as a testament to human ingenuity, offering a perfect balance of strength, flexibility, and environmental responsibility.

As we continue to face global challenges like climate change and resource scarcity, the role of corrugated packaging in creating a more sustainable supply chain becomes increasingly important.

From protecting delicate electronics to safely transporting fresh produce, corrugated flute packaging plays a crucial role in our daily lives, often without us even realizing it. Its ability to adapt to changing market needs, coupled with ongoing innovations in materials and design, ensures that corrugated packaging will remain a cornerstone of the packaging industry for years to come.

As consumers and businesses alike become more environmentally conscious, the inherent sustainability of corrugated flute packaging positions it as a packaging solution of the future.

By choosing corrugated, we’re not just protecting our products – we’re taking a step towards protecting our planet.

GCB is on of the largest Flute Corrugated packaging manufacturer in Malaysia.