As a supplier in Malaysia, we offer corrugated paper board and fluted sheets, essential for robust and lightweight packaging.

Corrugated cardboard, composed of a fluted sheet and linerboards, provides strength and durability.

Fluted sheets, central to corrugated cardboard, are ideal for protective packaging needs.

Corrugated cardboard, the core of our products, is a versatile packaging material consisting of a fluted corrugated sheet with one or two layers of flat linerboards. Produced on a Corrugator Machine, it is essential for making corrugated boxes. The corrugated medium sheet and linerboard(s) are crafted from various gsm paper rolls, including Medium, Test, and Kraft Liner.

With over 27 years in the industry, our company offers a variety of flute profiles such as BF, AF, EF, BAF, BBF, and AAF, catering to different packaging needs.

Golden Corrugated Box (GCB) Malaysia specializes in manufacturing high-quality corrugated board packaging solutions, including corrugated boxes, carton boxes, and custom box packaging. The company is committed to on-time delivery and sustainability in the corrugated carton industry.

GCB also provides paper pallet manufacturing as an eco-friendly alternative to wooden pallets for exporters. Their commitment to quality is evident in their attainment of ISO certifications and numerous industry awards.

Corrugated board also known as combined board, is a versatile material used to protect cargo on wooden or plastic pallets. Its quality can be assessed through various properties:

1. Moisture Content: Ideal range is 6.5-9.5%. Too low causes cracking, too high weakens compression strength.

2. Edge Crush Test: Evaluates force resistance per unit width, predicting box compression strength, reported in KN/m or lb/inch.

3. Burst Strength: The pressure needed to rupture the sheet, measured in KPa or lb/inch².

4. Box Compression Strength: A direct measurement of corrugated box performance, reported in kgf or N.

5. Flat Crush Test: Assesses the rigidity of flutes, reported in KPa.

Other characteristics include bending resistance, impact resistance, cushioning, shock absorption, tear resistance, and grammage (weight per square meter, reported in g/m²). Corrugated fiberboard's properties vary based on direction relative to the flutes and manufacturing orientation.

In the corrugated board industry, the weight and GSM (Grams per Square Meter) of the paper are crucial for determining board strength and durability. GSM, a universal paper measurement, signifies a paper's weight per square meter, like 80 GSM for office paper.

Corrugated board GSM, often from Kraft paper, varies to suit different needs: 115/125 GSM for standard durability, 140/150 GSM for heavier items, 185/200 GSM for increased protection, and 300 GSM for heavy-duty use.

The right GSM balances protection, cost, and presentation, influencing both packaging performance and aesthetics. However, this list is not exhaustive, as corrugated boards can be tailored with different GSMs to meet specific needs.

The choice of GSM impacts not only the protective qualities of the corrugated board but also its printability and overall aesthetic appeal. In packaging design, selecting the right GSM is a balancing act between protection, cost, and presentation.

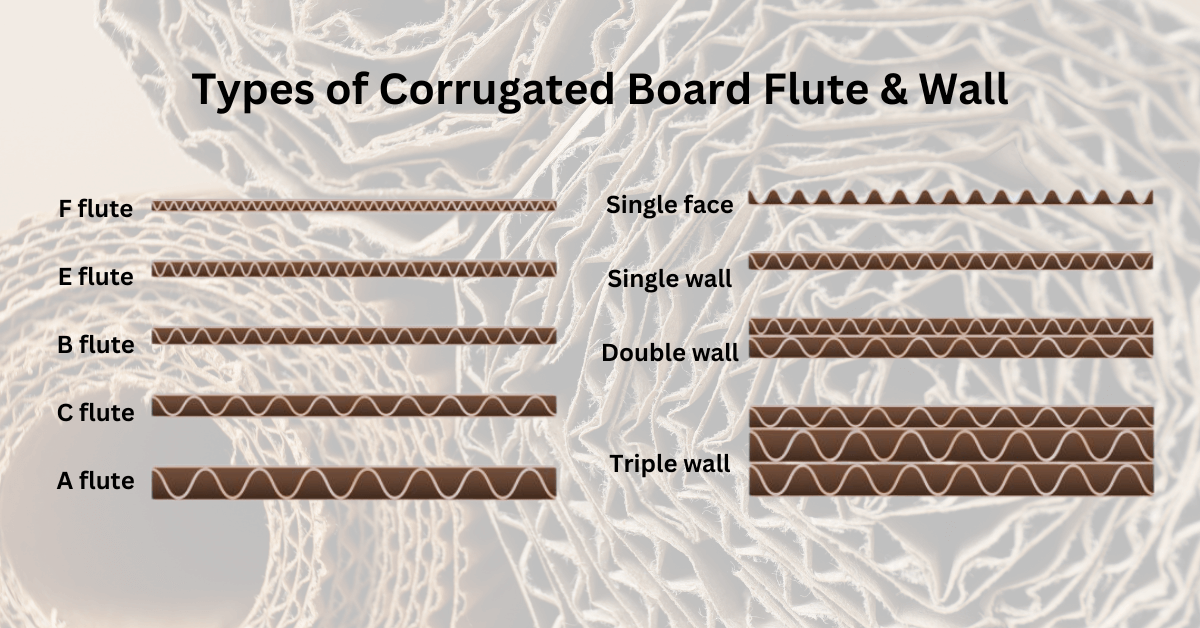

Corrugated board comes in different wall types, each offering varying degrees of strength and protection. The basic "single wall" consists of two liners with a single fluting layer, ideal for regular packaging needs. "Double wall" corrugated cardboard adds another layer of fluting and liner, enhancing rigidity and strength, suitable for heavier items or more delicate, valuable contents.

The most robust is the "triple wall," which includes an additional fluting and liner layer, providing maximum strength for heavy or large items like automotive parts or industrial equipment. Each wall type is designed to meet specific packaging challenges.

Corrugated cardboard's versatility largely stems from its fluting variations, which impact its strength and usage. Common fluting types include BF, AF, EF, BAF, EBF, BBF, AAF, BBBF, AAAF, and ABAF. Each type indicates a combination of flute sizes and layers; for example, BF (B-Flute) is medium in size, offering good cushioning and stacking properties. AF and EF are smaller, ideal for high-quality printing and lightweight items. Multiple layers like AAF (double A-Flute) or BBBF (triple B-Flute) enhance strength and durability, suited for heavier items. The selection of fluting types is critical in designing packaging that meets specific strength, cushioning, and size requirements.

At GCB, we take pride in producing different fluting types such as BF, AF, EF, BAF, EBF, BBF, AAF, BBBF, AAAF, and ABAF. Here are common types of fluting variations in corrugated paper cardboard:

Corrugated board is a sturdy packaging material made from three layers of paper: an outer liner, an inner liner, and a fluted corrugated sheet between them. This design provides excellent strength and durability for shipping and packaging, protecting items from damage while being lightweight.

The available paper grades for outer and inner liners in cardboard manufacturing include various options to suit different needs. These include KRAFT (K), which is virgin Kraft paper, and TEST 2 (T2), a partly recycled liner paper. TEST 3 (T) is a fully recycled liner, while CHIP (C) uses waste-based liners. FULLY BLEACHED WHITE (BW) is a fully bleached Kraft liner, and WHITE TOP (WT) is a white-coated recycled liner. MOTTLED KRAFT (MK) is a mottled white Kraft paper, and OYSTER (OY) is a mottled test liner. SEMI CHEM (SC) utilizes virgin fibers processed using a neutral sulphite semi-chemical method, and WASTE BASED (WB) consists of 100% recycled fibers. The last two grades are often used for flutes but can also serve as liners.

Our cardboard products are made from various GSM of paper rolls, consisting of Medium, Test, and Kraft Liner.

Paperboard and cardboard, both used in packaging, differ in their structure and applications. Paperboard, a single-layer, thick, paper-based material, is lightweight yet sturdy, commonly used for consumer goods packaging like cereal boxes. It’s easily shaped and cut, ideal for intricate packaging designs. Cardboard, often in the form of corrugated carton boxes, consists of multiple layers, including a fluted or corrugated layer and flat linerboards. This multi-layered structure provides enhanced strength and durability, making corrugated boxes particularly suitable for shipping and handling heavier loads.

The environmental benefits of using corrugated cardboard for packaging include:

These factors make corrugated cardboard a popular choice for eco-conscious packaging solutions.

Innovations in corrugated cardboard design for enhanced sustainability include the development of stronger and lighter materials to reduce resource usage, the integration of biodegradable coatings to replace plastic laminates, and improvements in recycling processes to increase material recovery. Additionally, advancements in manufacturing technologies have led to more energy-efficient production methods, further reducing the environmental impact of corrugated cardboard production.

Golden Corrugated Box (M) Sdn Bhd (GCB) was formerly known as Corrugated Carton Packaging Enterprise (CCPE) and it was incorporated since 24th July 1996. With its humble beginning in a rented premises, the company commenced its business activity as a converter of corrugated carton boxes.

No:7, Jalan Perusahaan Beranang 2, Kawasan Perindustrian Beranang, 43700 Beranang, Selangor Darul Ehsan, Malaysia.

© 2025 Golden Corrugated Box (M) Sdn Bhd. 200001020200 (522807-H). All Rights Reserved